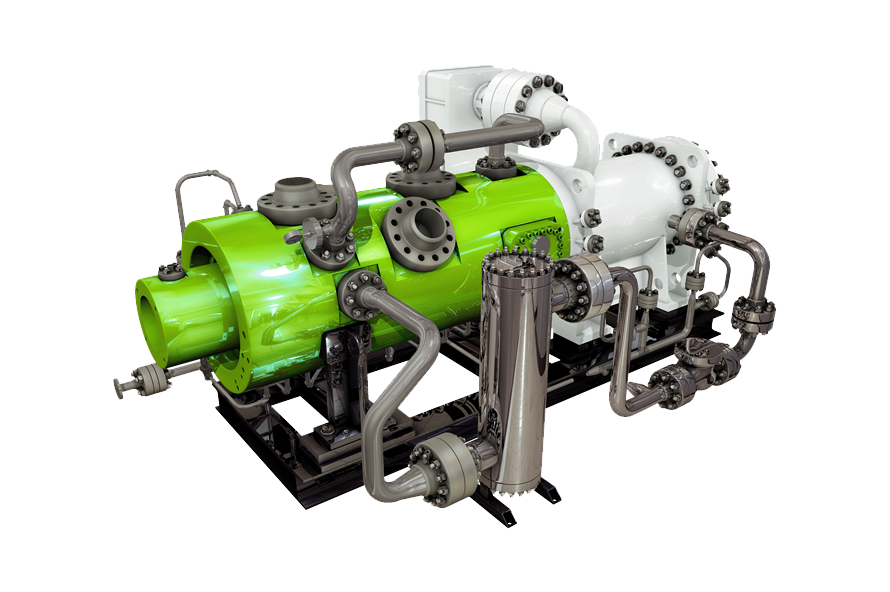

Integrated Motor-Compressor System

Emission free advanced centrifugal compressor technology with an electric motor driver in a single, completely sealed casing –up to 20 MW and up to 18,000 rpm

The system is driven by high-speed motor and high-frequency drive technology. The pressurized, induction motor includes a laminated rotor with a squirrel cage—a design proven by more than four million operating hours in industry-wide applications.

With Active Magnetic Bearings (AMB) technology, the rotor is levitated by a control system that precisely regulates the rotor spacing to avoid all parts contact and friction. This eliminates the need for lubricant thereby solving the problem of leak-prone lube oil systems used with conventional bearings. The AMB design maintains rotor levitation during starts, normal operation, and stops including emergency shutdowns. Ball bearing back-up allows the machine to stop without damage.

The drive is highly efficient over a very wide operating range, with the same hardware capable of driving the motor at low speeds and all the way up to 300 Hz, then helping reduce power consumption.

For an optimized experience, Power Conversion provides you with a process optimization service and real-time simulation for an efficient commissioning.