October 3, 2025

Parramatta Light Rail Sydney, Australia

GE Vernova was responsible for delivering both the Traction Power Substations (TPS) and the stray current monitoring system for the Parramatta Light Rail.

The Parramatta Light Rail is one of the New South Wales Government’s major infrastructure projects, designed to serve the growing population of Greater Sydney. It spans a corridor that starts from Westmead and extends to Carlingford, passing through the Parramatta central business district and Camellia. The project required highly integrated electrical infrastructure capable of meeting strict technical specifications while also operating seamlessly within a constrained urban environment.

This light rail line covers a distance of 12 km and operates at high frequency, providing a link between Westmead and Carlingford.

Challenge

The design needed to accommodate demanding performance standards, including protection coordination, environmental resilience, and compliance with external stakeholder requirements. Simultaneously, spatial efficiency was a critical driver, necessitating compact substation layouts and strategic internal component placement to align with site limitations.

Additional challenges stemmed from strict interface conditions both physical and functional that required attention to equipment arrangement, building access orientation, and communication system integration. Delivering a system that balanced performance, compliance, and constructability in such a confined and highly regulated context was a key aspect of the engineering.

Solutions

GE Vernova successfully delivered seven fully engineered, manufactured, and commissioned Traction Power Substations. Each substation is designed to supply 1.5 MW of 750 V DC power. Substation earth bars within the TPS buildings were engineered to meet the grounding requirements of each installed equipment, ensuring compliance with protection, safety, and operational standards. To continuously supervise and alert to the performance of the rail insulation, a Stray Current Monitoring System was designed and installed. The system measures the rail-to-earth potential along the alignment under operational conditions, complete with central analysis, visualization, signaling and archiving capabilities at the Central Evaluation Unit installed as a virtual machine in the Operation and Control Centre.

Main components

| 11 kV switchgear |

| 11 kV/590 V rectifier transformer |

| 11 kV/415 V auxiliary transformer |

| 11 kV/415 V depot kiosk transformer |

| 240 V AC distribution board |

| 750 V DC switchboard and rectifier |

| 125 V DC charger and batteries |

| Rail earth contactor panel & stray current collection |

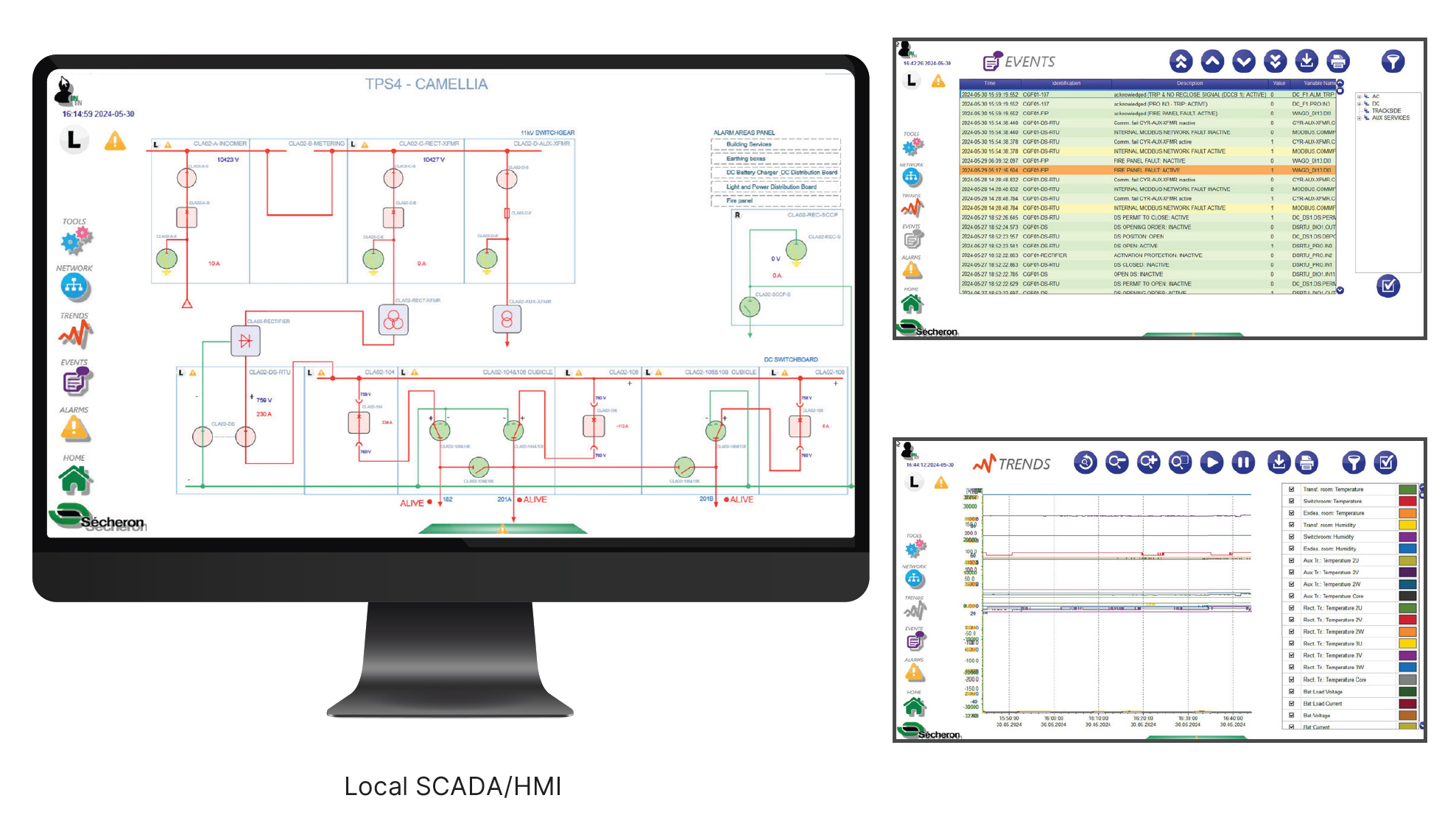

| Local SCADA/HMI |

A local SCADA/HMI is provided for the user to control and monitoring the entire traction power substation.

The system collects information from all different parts of the substation, processes the data and displays it on the local SCADA. In addition, trending and storage of voltage, current and temperature values over extended periods of time.

The selection of local or remote control is via a keyswitch on the front of the panel.

Benefits

- Off-site system integration of the traction power systems equipment in containerized substations allowed for reduced commissioning duration and minimized interface risks.

- Custom engineering - By closely aligning with the client’s specifications, we ensured design compliance, and compatibility with project-specific technologies. This contributed to ease of use and optimised fault finding.

- Local engineering support - Our ability to respond quickly on-site and design in accordance with standards such as TfNSW specifications and AS (Australian Standards), etc. enabled highly tailored system configurations and close technical support throughout the project life cycle.

- High reliability and availability - N-1 redundancy is built into both power systems and cooling infrastructure to ensure no signal point of failure affects system availability. Remote bypass and isolation capabilities enable fast recovery and operational continuity, even in fault conditions.

Looking at the future

GE Vernova's Power Conversion & Storage business has a strong track record in delivering traction power systems for DC light rail projects across Australia, including completed systems in Canberra, Newcastle, and Gold Coast, as well as ongoing design and engineering engagements in Canberra and the mining space.

As one of the flagship infrastructure initiatives led by the New South Wales (NSW) government, this project further reinforced GE Vernova’s leadership and reputation in Australia’s DC light rail power systems sector.

Building on this foundation, we are prepared to support the next generation of electrified DC rail projects globally with scalable, future-ready power technologies that align with long-term transport vision.